R&D

-

Vysokoteplotní MOCVD reaktor pro tenkovrstvé pokrývání oxidu kovu a nitridu kovu na substráty do 150mm

26/4/2018

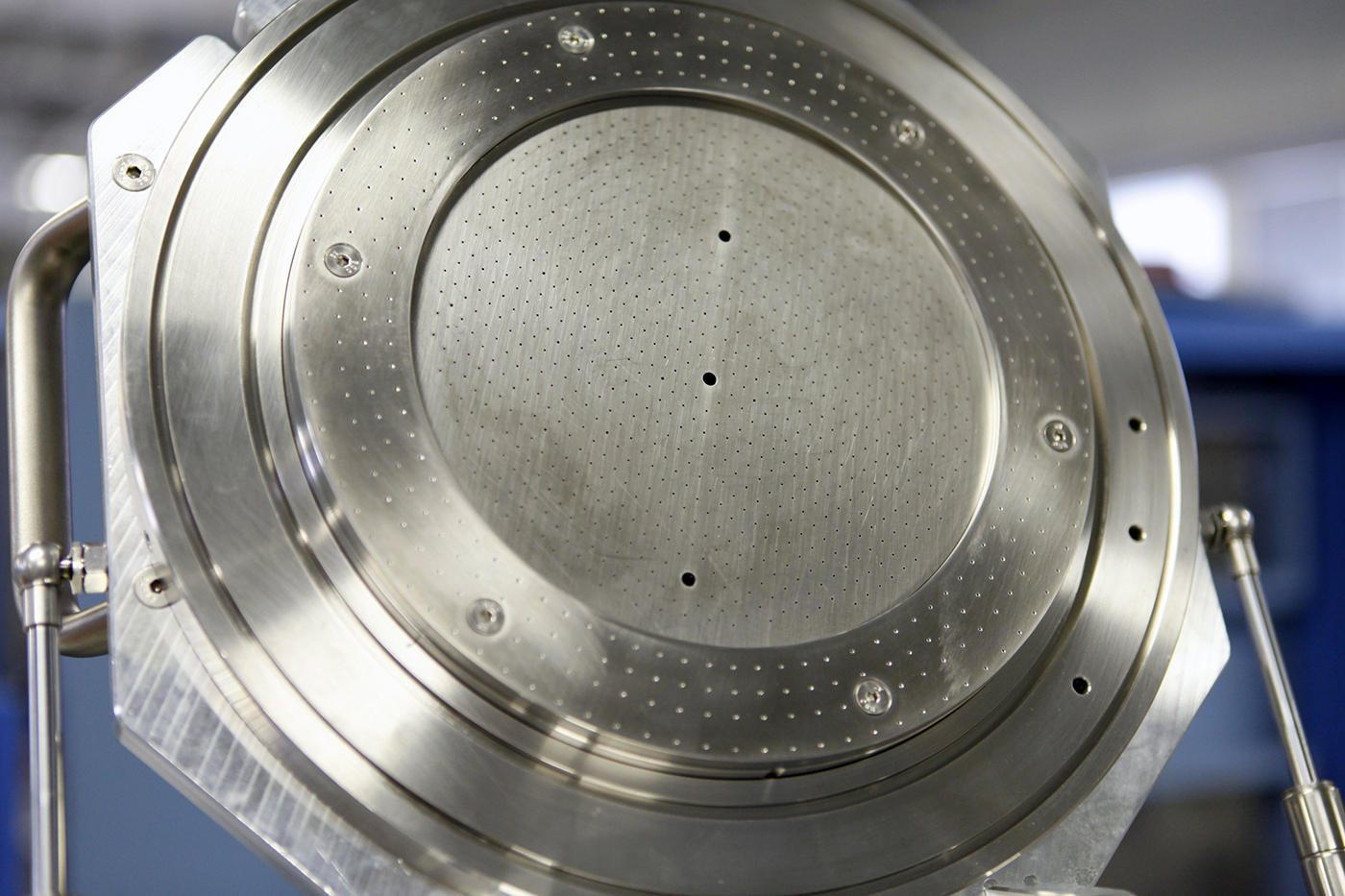

Within national R&D project we developed (with the technical support of University of Technology and CEITEC) this unique reactor including the MOCVD gas panel for metal nitride thin film depositions on wafers with sizes up to 150mm. This reactor was designed on the basis of first MOCVD prototype for metal-oxide thin films where up to three different precursors (+ 1 reactant) could be delivered simultaneously into the deposition chamber through the special showerhead (for ternary and quaternary alloys). Thus, we are not limited by deposition of single oxides only. Perfect solution for R&D laboratories and Institutes.

MOCVD reactor and load-lock chamber are designed separated each other for possible installation of load-lock chamber in clean rooms.

Vlastnosti

- Process temperature for metal-oxid layers up to 750ºC

- Process temperature for metal-nitride layers up to 1100ºC

- Specially designed gas showerhead system

- Height adjustable substrate holder (stainless steel or silicon carbide coated graphite susceptor)

- Substrate rotation up to 200rpm

- Wafer size up to 150mm

- Load-lock Automation

- Clean-room ready

Procesy

- Metal oxides: TiO2, HfO, ZrO2, ZnO, BaTiO3, PZT

- Metal nitrides: InN, GaN, AlN

More articles

-

Vysokoteplotní zařízení pro aktivaci příměsí v polovodičových SiC substrátech

Výzkum a vývoj SiC VTR reaktoru s podporou TAČR – projekt FW10010021 v rámci programu TREND (01/2024 až 12/2025) Cílem projektu...pokračovat

Číst více -

Česko-Japonský R&D project: ALD reaktor pro Minimal Fab

SVCS Process Innovation and HORIBA STEC will cooperate in the development of Minimal Fab design of the Plasma Enhanced Atomic...pokračovat

Číst více -

Plazmou aktivovaný ALD systém s unikátním zdrojem plazmy nízké teploty

SVCS Process Innovation and ISAC research teams will design together a plasma based ALD and ALEt equipment. The research will start with the standard ALD reactor design produced by ISAC, and plasma generation systems, gas and precursor distribution and controlling skills will be provided by SVCS.

Číst více