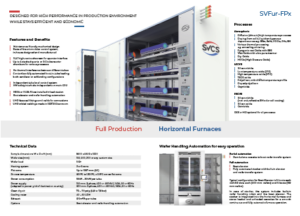

Products

Designed for High Performance in Production Environment while stays Efficient and Economic

Features and Benefits

- Maintenance friendly mechanical design

- State of the art modular control system, in-house designed and manufactured

- 10,4“ high-res touchscreen for operator interface

- Up to 4 stacked quartz or SiC tube reactor chambers for various procesess

- No thermal interference between different tubes

- Contactless fully automated boat-in-tube loading both cantilever or softlanding configurations

- Independent tube level control system

- HW safety interlocks independent on main CPU

- HEPA or ULPA filtres installed in load station

- Boat elevator and wafer handling automation

- UHP face seal fittings and welds for connections

- UHP orbital weldings made in 100/10 Cleanroom

Atmospheric Processes

- Diffusion (drive-in) high temperature procesess

- Doping from solid, liquid and gaseous dopant sources e.g.: BBr3, B2H6, POCL3, PH3, BN

- Various thermal processing e.g. annealing, sintering

- Pyrogenic Wet Oxide with External Burning System

- Wet Oxide with ultra pure steamer

- Dry Oxide

- HiPOx (High Pressure Oxide)

LPCVD Processes

- Silicon nitride

- Low temperature oxide (LTO)

- High temperature oxide (HTO)

- TEOS oxide

- Polysilicon, with tilt/flat temperature profile

- Doped polysilicon

- Oxynitride

PECVD Processes

- Silicon nitride (incl. anti-reflective SiN solar cell coating)

- Silicon oxide

- Oxinitride

DCE or HCl optional for all processes

Wafer Handling Automation

Partial automation

- Stand-alone cassette to boat wafer transfer system

Full automation

- Boat elevator

- Fully automated stocker with built-in elevator and wafer transfer system

Typical configuration for Boat Elevator is 5 boats each with 50 slots each (200 mm wafers) and 6 boats (150 mm wafers).

In case of stocker, the system includes built-in wafer handling robot and the boat elevator. The stocker is integrated into the horizontal furnace and stores loaded and unloaded cassettes for a smooth continuous and fully automatic furnace operation.

Technical data

| Sample dimensions W x D x H (mm) | 5600 x 2600 x 1000 |

| Wafer size (mm) | 150, 200, 300 or any custom size |

| Wafer load | 100+ |

| Heating system | 3 or 5 zone |

| Flat zone | Up to 1067 mm (42″) |

| Process temperature | 200°C to 1300°C, ± 0.5°C across flat zone |

| Power consumption | 18kW – 30kW per tube |

| Power supply (adapted to power grid of destination country) |

150 mm: 3-phase, 400/480VAC, 140A, 50/60 Hz 200 mm: 3-phase, 400/480VAC, 160A, 50/60Hz |

| Clean dry air | 70 – 110 psig (4,8 to 7,6 bar) |

| Cooling water | 40 – 60 LPM |

| Exhaust | 210m³/h per tube |

| Options | Boat elevator and wafer handling automation |

-

India

India

India

India

MCube Technologies Pvt Ltd.

204, Ashok Sankul II, Ashok Nagar,

Off Range Hills Road,Shivajinagar, Pune-411007

Contact: Mr Akshay Patil

Mob: +91 (0) 9763 7180 58Office: +91 (0) 2025 5606 66 (Sales)

Email:

Email:

www.mcubetechnologies.com -

Israel

Israel

Israel

Israel

PicoTech Ltd.

17 HaMefalsim st,

Petach-Tikva, 4951447, IsraelTel.:+972-3-6356650

Email:

Email:Web-site: www.picotech.co.il

-

Singapore

Singapore

Singapore

Singapore

Sam Chan

Regional Business Network Pte Ltd

16 New Industrial Road

#04-08 Hudson Technocentre

Singapore 536204Tel: (65) 62809650

Fax: (65) 62809675

Mobile: (65) 96170912Web: www.rbnpl.com

-

Germany

Germany

Germany

Germany

European Market Partner BV

Park Reeburg 27

5261 GC Vught

The NetherlandsTel: +31 495 54 58 17

Cell: +31 6 24 759685

Email: -

Netherlands

Netherlands

Netherlands

Netherlands

European Market Partner BV

Park Reeburg 27

5261 GC Vught

The NetherlandsTel: +31 495 54 58 17

Cell: +31 6 24 759685

Email: -

France

France

France

France

Bruno MERCIER – Business Partner

Self entrepreneur

Expert in Microelectronics, MEMS and Clean room environment

Tel : + 33 6 62 47 30 42

Email:172 Rue des Bauges

74210 Doussard

FRANCE

-

Hong Kong + Taiwan

Hong Kong + Taiwan

Hong Kong + Taiwan

Hong Kong + Taiwan

Great Domain

Mark Chang

Enterprise Co., Ltd.

15-1F, No.37, Sec. 2, Sanmin Rd.,

Banqiao Dist., New Taipei City, Taiwan

Tel.: 0912-730-586

Fax: 0289538399

Email: -

Vietnam

Vietnam

Vietnam

Vietnam

AMST., CO. Ltd.

Mrs. Le Thi Thu Huong

48A, Alley 21 Phan Dinh Giot Str.

Thanh Xuan Dist., Hanoi

Vietnam

Tel: +84 2466831909Mobile: +84902245626

Email: info@amst.com.vn / sales@amst.com.vnWeb: www.amst.com.vn

-

Australia

Australia

Australia

Australia

UHP Australia Ply Ltd.

Unit 4, 20 Velediclion Road, Kings

Park NSW 2148, AUSTRALIA

Tel.: +61 (0)2 9676 6769

Mob.: +61 (0) 3904 3893

Email: -

Japan

Japan

Japan

Japan

VYTEK Ltd.

Mr. Vladimir Kovacik

Wisteria Komae bldg.3F

1-2-8 Izumi Honcho, Komae, Tokyo, 201-0003 Japan

Tel.:+81-3-3480-9082

Fax:+81-3-3480-9083

Email:

http://www.vytek.co.jp/ -

Korea

Korea

Korea

Korea

Sang-Hoon, Lee (Mr. Edward Lee)

Managing Director of SH Korea

#310-213, Ansan Distribution Complex

994-6, Wongok-dong, Danwon-gu,

Ansan-si, Gyeonggi-do, Korea.

zip code 15431

Fax: +82.31.8084.4744

web-site: www.shkorea.kr

Mobile: 82-10-4307-8412

Email: -

Taiwan

Taiwan

Taiwan

Taiwan

Sung Yuan Biotechnology Co., Ltd.

Mr. Thomas Liu

Sales Director

No.818, Wen-San Road, Up-Mountain village

Chung-Lin Hsiang, Hsin-Chu County 307,

Taiwan R.O.C

Tel: +886-3-5122.096 ext 101

Fax: +886-3-5925.308

Mobile: +886-938-365.326

Email:

Email: -

China

China

China

China

PELAS

Mr. Tony Wang

Shanghai PelaStar Materials Technology Co., Ltd

Room. 1102, Suncome Liauw’s Plaza, No. 738, Shangcheng Rd.Shanghai, 200120, China

Tel.: 86-21-51981110

Fax.: 86-21-51981109

Mobile: 13816658585

Email: -

Malaysia

Malaysia

Malaysia

Malaysia

SERMAX Engineering Pte, Ltd

(201025665Z)

11 Mandai Estate, #08-01 Eldix, Singapore 729908

Phone : +65-6710 7710

Fax : +65-6710 7710

Email: -

Turkey

Turkey

Turkey

Turkey

TESTONE TEKNOLOJI COZUMLERI SAN. VE TIC LTD. STI.

Gürsel Mah. İkbal Sok TestOne Binası No :7

Kağıthane-İstanbul

Tel: 0212 251 24 25

Fax: 0212 222 90 90

Email: -

USA

USA

USA

USA

SVCS CO.

1819 Main Street

Sarasota • Florida 34236 • USA

www.svcs.com

Email: